This is preliminary information, subject to change, and may contain errors. Any errors in this report will be corrected when the final report has been completed.

Investigator In Charge (IIC): Brazy, Douglass

The National Transportation Safety Board travelled to the scene of this accident.

Additional Participating Entities:

Matt Rigsby; Accident Investigation and Prevention (AVP); Washington, District of Columbia

Federal Aviation Administration / Flight Standards District Office; Seattle, Washington

Northwest Seaplanes Inc

~

In the foreground, a 6-passenger DHC-2 Beaver waits at the Friday Harbor Seaplanes base at the south end of Lake Washington in Renton. The seaplane that crashed off Whidbey Island was the company’s lone DHC-3 Otter, a larger model that carries 10 passengers.

Friday Harbor Seaplane Tours

Location: Freeland, Washington

Accident Number: DCA22MA193

Date and Time: September 4, 2022, 15:09 Local

Registration: N725TH

Aircraft: DEHAVILLAND DHC-3

Injuries: 10 Fatal

Flight Conducted Under: Part 135: Air taxi & commuter - Scheduled

On September 4, 2022, at 1509 Pacific daylight time, a de Havilland DHC-3, N725TH, was substantially damaged when it impacted Mutiny Bay near Freeland, Washington, and sank. The pilot and 9 passengers were fatally injured. The airplane was operated as a Title 14 Code of Federal Regulations (CFR) Part 135 scheduled flight. The US Coast Guard and good Samaritans responded to the accident site.

The accident occurred during the pilot’s second trip of the day; each trip involved multiple flight legs. A review of Federal Aviation Administration (FAA) tracking data revealed that the accident flight departed from Friday Harbor Seaplane Base (W33), Friday Harbor, Washington, about 1450 with a destination of Renton Municipal Airport (RNT), Renton, Washington. The track data indicated the airplane flew a southerly heading before turning south-southeast. The en route altitude was between 650 and 975 ft above mean sea level (msl), and the groundspeed was between 115 and 125 knots. At 1508:43 the altitude increased to 1,125 ft, and the groundspeed reduced to 109 knots. At 1508:49, the altitude decreased to 875 ft and the groundspeed reduced to 100 knots. The tracking data ended at 1508:51, at an altitude of 700 ft and groundspeed of 55 knots.

Witnesses near the accident site reported that the airplane was in level flight before it entered a slight climb, then pitched down in a near-vertical descent. The airplane continued in a nose-low, near-vertical descent until it impacted water in Mutiny Bay. Several witnesses described the airplane as “spinning,” “rotating,” or “spiraling” during portions of the steep descent. One witness reported hearing the engine/propeller noise and noted that he did not hear any “pitch change” in the noise.

The pilot began working for the operator in 2013 and was one of two pilots who flew the DHC3, which he began flying in 2017. He had accrued a total of 4,686 flight hours as of May 31, 2022. His total flight hours in the DHC-3 have not yet been determined. He received training in emergency drills and procedures in May 2022, and an aircraft competency check in June 2021.

The airplane’s most recent 100-hour inspection was performed on September 1, 2022. Included at that time were recurring inspections required by Airworthiness Directives (AD) 83-04-05 (control column lower assembly) and 2011-18-11 (elevator control tabs). A left-hand rudder retract cable was replaced during the 100-hour inspection. The previous 100-hr inspection was performed on August 16, 2022, which also included the recurring AD inspections noted above. At that time, the horizontal stabilizer hinge bolts, a right-hand engine ignitor, and a left-hand float locker latch were replaced.

The airplane was not equipped nor was it required to be equipped with a flight data recorder or cockpit voice recorder. A King 560 Enhanced Ground Proximity Warning System was installed, which can retain some parametric flight data; however, the unit was not crash-protected. Some floating debris was recovered by local authorities and good Samaritans who responded to the accident site. This included three 6-ft sections of aluminum honeycomb panels used for flooring in the airplane, a seat cushion and seat belt, and small sections of foam, consistent with a modification made to the landing floats.

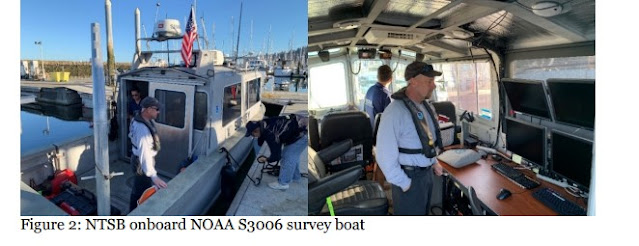

The NTSB structure’s group chairman went on board vessels provided by the Washington Department of Fish and Wildlife, the National Oceanic and Atmospheric Administration (NOAA) and the University of Washington to collect data using varying types of sonar equipment.

A sonar survey of the accident area located the main wreckage and debris field at a depth of about 190 ft.

At 1515, the automated weather observing station at Jefferson County International Airport (0S9), located 10 nautical miles northwest of the accident site, reported wind from 310° at 10 knots, visibility 10 statute miles, few clouds at 4,000 ft and 7,500 ft, broken clouds at 9,000 ft, temperature 20°C, dew point 14°C, and an altimeter setting of 30.02 inches of mercury.

Additionally, pilots flying in the vicinity of the accident area reported turbulence and a scattered cloud layer at 2,300 ft.

The US Navy will be assisting the NTSB with the wreckage recovery, and examination will begin once the wreckage is recovered.

Douglass Brazy, Investigator In Charge, onboard NOAA S3006 survey boat.

Aircraft and Owner/Operator Information

Aircraft Make: DEHAVILLAND

Registration: N725TH

Model/Series: DHC-3

Aircraft Category: Airplane

Amateur Built:

Operator:

Operating Certificate(s) Held: Commuter air carrier (135)

Operator Designator Code:

Meteorological Information and Flight Plan

Conditions at Accident Site: VMC

Condition of Light: Day

Observation Facility, Elevation: K0S9

Observation Time: 15:15 Local

Distance from Accident Site: 10 Nautical Miles

Temperature/Dew Point: 20°C /14°C

Lowest Cloud Condition: Few / 4000 ft AGL

Wind Speed/Gusts, Direction: 10 knots / , 310°

Lowest Ceiling: Broken / 9000 ft AGL

Visibility: 10 miles

Altimeter Setting: 30.02 inches Hg

Type of Flight Plan Filed: Company VFR

Departure Point: Friday Harbor, WA (W33)

Destination: Renton, WA (RNT)

Wreckage and Impact Information

Crew Injuries: 1 Fatal

Aircraft Damage: Substantial

Passenger Injuries: 9 Fatal

Aircraft Fire: Unknown

Ground Injuries: N/A

Aircraft Explosion: Unknown

Total Injuries: 10 Fatal

Latitude, Longitude: 47.99032,-122.58502

Those who may have information that might be relevant to the National Transportation Safety Board (NTSB) investigation may contact them by email witness@ntsb.gov, and any friends and family who want to contact investigators about the accident should email assistance@ntsb.gov. You can also call the NTSB Response Operations Center at 844-373-9922 or 202-314-6290.

Federal Aviation Administration order points to one possible cause of Whidbey seaplane crash

National Transportation Safety Board investigators look at the recovered engine of the DHC-3 Otter that crashed on September 4 off Whidbey Island.

The Federal Aviation Administration has issued a warning regarding potential weaknesses in parts of the tail of Otter seaplanes, the same type of aircraft that crashed off Whidbey Island last month.

The emergency airworthiness directive, issued Tuesday, warns of potential cracks and corrosion in the movable surface of the horizontal tail that controls the plane’s pitch. The directive is not a result of the investigation into the fatal crash in Mutiny Bay, which killed 10 people, but does suggest one possible cause.

The directive warns that, if not addressed, the cracks and corrosion could lead to a structural failure in the tail and “loss of control of the airplane.”

A person close to the Mutiny Bay crash investigation said the directive was spurred when mechanics discovered a crack in the tail of another Otter during a routine inspection unrelated to the deadly crash.

The person spoke anonymously because they were not authorized to release information about the ongoing National Transportation Safety Board investigation.

The directive states that the FAA received “multiple recent reports” of cracks in the same part: the elevator, a movable surface at the rear of the horizontal tail.

The Federal Aviation Administration has issued a warning regarding potential weaknesses in parts of the tail of Otter seaplanes, the same type of aircraft that crashed off Whidbey Island last month.

The emergency airworthiness directive, issued Tuesday, warns of potential cracks and corrosion in the movable surface of the horizontal tail that controls the plane’s pitch. The directive is not a result of the investigation into the fatal crash in Mutiny Bay, which killed 10 people, but does suggest one possible cause.

The directive warns that, if not addressed, the cracks and corrosion could lead to a structural failure in the tail and “loss of control of the airplane.”

A person close to the Mutiny Bay crash investigation said the directive was spurred when mechanics discovered a crack in the tail of another Otter during a routine inspection unrelated to the deadly crash.

The person spoke anonymously because they were not authorized to release information about the ongoing National Transportation Safety Board investigation.

The directive states that the FAA received “multiple recent reports” of cracks in the same part: the elevator, a movable surface at the rear of the horizontal tail.

In addition, there have been a series of other nonfatal Otter incidents involving elevator failure.

A sudden elevator failure can cause a plane to pitch immediately nose-down, similar to the trajectory reported by some witnesses of the September 4 crash, said Douglas Wilson, a Seattle-based seaplane pilot and president of aviation consulting firm FBO Partners.

The Mutiny Bay crash plane was a de Havilland Canada DHC-3 Otter turboprop operated by Renton-based Friday Harbor Seaplanes.

Todd Banks, president of Kenmore Air, which flies similar Otter seaplanes, said investigators could be examining as many as a dozen possibilities, ranging from structural failures of the airframe to a pilot health emergency.

However, he said the timing of the FAA directive is “interesting” and that something going wrong with the control surface on the tail is likely one focus of the investigation.

NTSB spokesperson Peter Knudson said via email Friday that in the Mutiny Bay crash investigation “the wreckage examination and records review are still underway.”

“We will be looking at all the structure and systems on the airplane to determine if there were any malfunctions or failures that contributed to the accident,” he said.

An FAA spokesperson said Friday “the investigation is ongoing. No cause has been determined.”

Multiple recent reports of cracks

Tuesday’s FAA directive states that it was “prompted by multiple recent reports of cracks in the left-hand elevator auxiliary spar.”

Delivered weeknights, this email newsletter gives you a quick recap of the day's top stories and need-to-know news, as well as intriguing photos and topics to spark conversation as you wind down from your day.

This unsafe condition, if not addressed, could lead to “elevator failure, with consequent loss of control of the airplane,” the directive states.

The auxiliary spar is the trailing edge of the elevator, which flaps up or down to move the nose of the plane up or down.

The left elevator is interconnected with and moves in sync with the flaps on the wings to enhance stability.

The last DHC-3 Otters were built in the late 1960s. Today’s fleet of aging workhorse seaplanes has been modified and rebuilt over the years. They need constant maintenance to fight the corrosive effects of seawater.

The FAA directive mandates “repetitive detailed visual inspections of the entire left-hand elevator auxiliary spar for cracks, corrosion, and previous repairs, and depending on the findings, replacement of the left-hand elevator auxiliary spar.”

The wording requires urgent action, indicating the danger is considered serious.

Within three days of receipt of the directive all Otter operators are instructed to “remove the left-hand elevator tab from the elevator and perform a detailed visual inspection.”

Results of the inspections have to be reported back to the FAA within 10 days.

Wilson of FBO Partners said daily visual inspection of the elevator is not easy on a seaplane.

That’s because when a seaplane is docked, with one of its floats tight against the dock, the tail is at a height and a distance from the dock that makes a thorough visual inspection difficult. The only way to do so is to pull the plane out of the water and do a complete inspection on dry land, Wilson said.

Following a 1995 DHC-3 Otter in-flight vibration incident in Ketchikan, Alaska, caused by cracks in an elevator tab, the operator’s director of maintenance told NTSB investigators that “the airplane’s tail is approximately 10 to 11 feet above the ground and is very difficult to examine during pre-flight.”

Past elevator failure incidents

The FAA did not detail where any of the recent multiple reports of cracks in Otter elevator spars occurred.

In-depth journalism takes time and effort to produce, and it depends on paying subscribers. If you value these kinds of stories, consider subscribing.

However, several past accident reports show elevator failure as a cause.

In May, a DHC-3 Otter crashed nose down into forested terrain while coming in to land in Yakutat, Alaska. The pilot had noticed the elevator not responding fully to his controls at various points in the flight and the airplane pitching up alarmingly.

No one died but the pilot and three passengers on board suffered serious injuries. The NTSB said that accident is still under investigation.

In 2014, an Otter experienced “an anomalous in-flight vibration and uncommanded nose down pitch during cruise flight in the vicinity of Homer, Alaska,” an NTSB report states.

No one was injured. But the airplane’s right elevator “sustained substantial damage.”

In 2015, another Otter in cruise flight near Skwentna, Alaska, also experienced unusual vibration. After landing, the tab on the right-hand elevator, which had been poorly repaired, was found to be damaged.

With investigators not yet finished examining the wreckage from the Mutiny Bay crash, it’s impossible to definitively point to the cause. For sure, they will be looking for evidence of elevator failure as a serious focus of the inquiry.

According to the GoFundMe, setup by a fellow employee at Northwest Seaplanes, Jason Winters was a loving father and husband.

Aircraft crashed under unknown circumstances into Mutiny Bay, Whidbey Island, Washington

Date: 04-SEP-22

Time: 22:09:00Z

Regis#: N725TH

Aircraft Make: DEHAVILLAND

Aircraft Model: DHC-3

Event Type: ACCIDENT

Highest Injury: FATAL

Total Fatal: 10

Flight Crew: 1 Fatal

Pax: 9 Fatal

Activity: ON DEMAND

Flight Phase: EN ROUTE (ENR)

Operation: 135

Aircraft Operator: WEST ISLE AIR

Aircraft Missing: No

Damage: SUBSTANTIAL

City: WHIDBEY ISLAND

State: WASHINGTON

Wreckage of de Havilland Canada DHC-3T Turbine Otter, N725TH, that crashed into Washington's Mutiny Bay.

Applied Physics Laboratory - University of Washington

The wreckage of a floatplane that crashed into the waters of Washington state's Puget Sound last week has been found on the seafloor, The National Transportation Safety Board said Monday.

Ten people - including a married couple from Minnesota - were on the Sunday flight from Friday Harbor in the San Juan Islands to the Seattle suburb of Renton when it crashed on September 4.

The NTSB said the depth and motion of the water hid the wreckage for several days, The Seattle Times reported.

Sonar located a "large section" similar in length and width to the plane about 190 feet below the surface of Puget Sound near Whidbey Island, according to spokesperson Jennifer Gabris.

Investigators, the National Oceanic at Atmospheric Administration and the University of Washington's Applied Physics Laboratory scoured a 1.75-by-0.75-mile area where witnesses said the plane had crashed.

Because of the depth and 3-5 knot currents, the NTSB is seeking a remotely operated vehicle to recover the wreckage. The NTSB had said that crash details, including the cause of the crash, couldn't be determined until more of the wreckage was found.

A family member confirmed that Luke Ludwig, 42, and his wife, Rebecca Ludwig, 42, were among those presumed dead in the plane crash. The married couple with kids lived in Excelsior; their kids are safe and with other family.

The only body that has been found was identified last week as Gabby Hanna of Seattle.

Kathe Baker, her husband, son and grandchildren pose with Friday Harbor Seaplanes pilot Jason Winters in this DHC-3 Otter on Saturday, a day before another flight Winters piloted went down off Whidbey Island.

The Friday Harbor Marina is a popular destination for Seattle-based floatplanes. The plane that crashed Sunday with 10 passengers and one pilot aboard taken off from Friday Harbor, on San Juan Island, headed for Renton, on Lake Washington.

A sign advertises Friday Harbor Seaplanes at the Port of Friday Harbor Marina on Monday, the day after one of the company’s flights crashed into Puget Sound off Whidbey Island.

Seaplanes have been part of aviation culture in the Pacific Northwest since Boeing started building them on Lake Union a century ago. Here, seaplanes sit on the tarmac at Northwest Seaplanes at the Renton Municipal Airport in Renton. In the background are Boeing 737s manufactured at Boeing’s Renton plant.

Seaplanes are a Seattle icon. Their pilots are mystified by tragic crash

Last Sunday’s fatal crash of a seaplane off Whidbey Island stunned and mystified the region’s aviation community, for whom sturdy de Havilland floatplanes have been a routine yet thrilling part of life here.

Seaplanes have been part of Seattle’s fabric since Boeing’s first plane took off from Lake Union in 1916. Today they provide regular commuter and tour service throughout the Pacific Northwest from Seattle to the San Juan Islands, Alaska and British Columbia.

Ten people died in Sunday’s fatal flight. Its trajectory — a normal takeoff and climb with no significant weather and about 18 minutes of routine flying before a sudden, steep plunge into the sea without a distress call — is, for now, unexplained and deeply disturbing.

Colleen Mondor, an author who specializes in investigating air accidents in Alaska involving similar aircraft, said this flight pattern before such a disastrous end is very strange.

“That sure sounds like a stall,” Mondor said. “It’s weird to be 18 minutes into a flight and all of a sudden to exhibit that kind of behavior with the aircraft.”

The plane was a de Havilland Canada DHC-3 Otter turboprop operated by Renton-based Friday Harbor Seaplanes.

Though this aircraft type has suffered a rash of accidents in Alaska over seven decades of service, those have almost exclusively been tied to poor pilot decisions in rough terrain and bad weather. The aircraft is considered safe.

“They’re older. But they’re really good airplanes,” Mondor said. “They’ve flown for a long time for good reason. They don’t fall out of the sky.”

Jay Todhunter, chief pilot with Kenmore Air, which runs a much bigger floatplane operation than Friday Harbor Seaplanes, described the Otter as “a great airplane to fly.”

“We all love it. It’s perfect for what we use it for. It’s a fairly tame airplane, for the most part easy to fly,” he said.

Todhunter said pilots at the two companies know each other. He had occasionally shared casual conversations on the dock at Friday Harbor with Jason Winters, the pilot on Sunday’s fatal flight.

“There’s kind of a community within the pilot group here,” Todhunter said. “It’s a tragedy and it’s in all of our thoughts right now.”

An icon of Pacific Northwest aviation

Seattle seaplane flights typically delight first-time flyers as they look with fresh eyes from the air at the region’s breathtaking scenery of mountains, lakes and ocean.

Kenmore Air flies out of both Lake Union and a seaplane base at Kenmore on the north end of Lake Washington. Vancouver, B.C.-based Harbor Air and charter company Seattle Seaplanes also fly in and out of Lake Union, while Friday Harbor Seaplanes operates out of a base at the southern tip of Lake Washington in Renton.

These commuter and tourist seaplanes are permitted to fly only in daytime, clear weather conditions. They cannot take off unless the cloud ceiling is above 1,000 feet with visibility of at least two miles ahead. Fog means canceled flights. Winter flying is limited.

The most popular destinations include Friday Harbor, Orcas Island, Victoria, Vancouver and Desolation Sound in the northern reach of the Georgia Strait.

Many of the flyers are island residents commuting to Seattle and destinations beyond.

In addition, air charter company Seattle Scenics offers seaplane tour flights from Lake Washington at Renton and Kirkland. And there are thousands of takeoffs and landings performed by private noncommercial floatplanes in this region each month.

It’s not all tourists and commuters on these flights. The floatplanes ferry professionals of every description to and from the islands, including whale biologists, doctors, architects, attorneys, boat technicians and IT specialists.

The planes routinely transport perishable food to island restaurants and, when the ferries are down, essential supplies.

The more than 100-year history of floatplanes here has a grip on those in the business. Once flying catches the imagination, it tends to be passed along through generations.

Todd Banks, president of Kenmore Air, has been in the aviation business 31 years. His grandfather, Bob Munro, started operating seaplanes on Lake Washington and Lake Union in 1946.

“Seaplanes are vital part of the transportation system in the Northwest ... to access some of the most beautiful places in the world,” said Banks. “It’s been a privilege to be part of it.”

The DHC-3 Otter, seating 10 passengers, is an aging workhorse of this system. It was first built in the 1950s and a total of 466 were produced through 1967. Almost all those flying today have been updated from piston to more powerful turbine engines.

The Otter is a familiar sight even to Seattleites who’ve never flown in it. Kenmore uses it, along with a smaller six-passenger model called the DHC-2 Beaver, on the scenic flights that take off from Lake Union and top the downtown skyscrapers as they fly out.

Weighing in just below the 12,500 pound threshold above which regulations require a crew of two in the cockpit, it’s one of the largest airplanes that can be flown by a single pilot.

The Federal Aviation Administration aircraft registry shows Northwest Seaplanes, the parent company of Friday Harbor Seaplanes, with just a single DHC-3 Otter in its fleet — the one that crashed — along with four DHC-2 Beavers.

Kenmore Air has a current floatplane fleet of 10 Otters and seven Beavers.

The air navigation site used by pilots shows an average of 119 seaplane landings or takeoffs per day from Kenmore’s Lake Union base and 118 per day at its Lake Washington base in 2019. About a fifth of those are private seaplane operations without commercial passengers.

The same site shows the Lake Washington seaplane base at Renton used by Friday Harbor Seaplanes averaged 46 takeoffs or landings per week in 2020, a down year due to the pandemic.

Bulk of previous accidents occurred in wilderness

The Otter’s ability to take off in a short stretch and climb fast, which makes it ideal for Lake Union, also means it’s “one of the finest bush planes ever built,” said David Gudgel, Kenmore’s chief operating officer, referring to planes that can land and take off in the wilderness of Alaska.

There, the plane is used by multiple small operators for adventurous operations that have accounted for the bulk of Otter accidents.

“They’re landing in rivers and lakes and flying through mountains,” said Gudgel. “A lot of those (crashes) I think you’ll find are pilot error.”

The Geneva-based Bureau of Aircraft Accidents Archives compiled a comprehensive database stretching back 54 years to 1963 that shows 52 fatal DHC-3 Otter crashes, including Sunday’s.

Of those, 21 were military aircraft. The U.S. Army lost a few in Vietnam. Another eight were wheeled versions for land use or equipped with skis for snow landings. Of the 23 fatal civil floatplane accidents listed, 19 were in North America and caused 70 deaths.

The cause in many cases was attributed to the pilot making a choice to fly in bad weather. A few other accidents were caused by the pilot failing to balance the load in the cargo bay before takeoff, shifting the plane’s center of gravity.

Mondor said the vast majority of these Alaska backcountry accidents have been “very specific to pilot decision-making concerning load or weather decisions and not about the airplane.”

These accidents occurred in an environment much more hostile than the scheduled and charter commuter services operated out of Seattle.

“We don’t deal with the terrain and the weather that they deal with up there. It’s a lot different,” said Kenmore’s Todhunter.

The Swiss database shows no previous accidents for Friday Harbor Seaplanes or its parent company, Northwest Seaplanes.

Kenmore has suffered one fatal crash, in October 1977, when seven people died flying over Stevens Pass in a DHC-2 Beaver. The investigation report found the pilot hadn’t balanced the aircraft’s load and made “improper in-flight decisions,” flying too low.

In the ensuing 45 years, Kenmore has had no fatalities.

The analysis of previous DHC-3 Otter accidents leaves Sunday’s crash mystifying.

The flight path was straightforward. The pilot was experienced.

Though it was a little windy, there was nothing troubling in the weather.

Chuck Perry, who has been a pilot for more than 36 years and was Kenmore’s chief pilot before Todhunter, said the Otter is a heavy, stable airplane in high wind.

The plane was full Sunday, but if the load had been unbalanced that should have been clear on takeoff.

In addition to examining the wreckage once it is retrieved, investigators will look at the plane’s maintenance records, searching for any possible mechanical anomaly.

Northwest Seaplanes deferred questions to National Transportation Safety Board investigators.

A stressful time

The entire aviation community has been through a financial crisis that forced layoffs during the pandemic-driven air travel downturn. That has stressed airplane operations everywhere, from Boeing to major airlines to aircraft repair and overhaul shops.

Bureau of Transportation Statistics, which provides data on scheduled passenger services, though not similar figures for charter flights, shows that Friday Harbor Seaplanes carried nearly 3,400 passengers in pre-COVID 2019 but just half that number in 2020.

However the business rebounded in 2021, with more than 5,500 passengers carried.

Kenmore’s Banks said that in this “very small, niche part of aviation” he knows fairly well Shane Carlson, who runs Northwest Seaplanes, founded by his dad, Clyde Carlson.

“They do a good job,” Banks said of his smaller competitor.

He texted Shane on Sunday after the accident to express condolences.

“It’s a tragedy,” Banks said. “It’s just a hard time for us right now.”

Banks said he understands if people are now afraid to fly on a seaplane. This week, one customer canceled a charter flight with Kenmore.

“We are more than happy to give people refunds, or whatever they want to do, if they’re feeling anxious about it,” Banks said.

Todhunter, who spoke Tuesday before he took off on a sightseeing flight, said he remains “very confident in what we do.”

“I don’t know what happened in this accident, I don’t know why it happened,” he said. “But I feel very good about the way we do things. We like to play it safe.”

Perry, his predecessor as chief pilot, said, “I just really hope that they can get that airplane out of the water, because it’ll tell the story.”

“That’s going to be all-important to figuring out what happened,” he said.

Tom Chapman from the National Transportation Safety Board addresses the media in Mukilteo, Snohomish County, Washington.

U.S. Coast Guard sent this bulletin at 09/06/2022 09:00 AM EDT

News Release

U.S. Coast Guard 13th District Pacific Northwest

Contact: 13th District Public Affairs

Office: (206) 220-7237

After Hours: (206) 220-7237

13th District online newsroom

Coast Guard releases names of passengers, crew of crashed seaplane

SEATTLE -- The Coast Guard is releasing the names of the passengers and crew of the sea plane that crashed into the waters of Mutiny Bay off Whidbey Island on Sunday afternoon.

Pilot: Jason Winter

Passengers:

Patricia Hicks

Sandra Williams

Lauren Hilty

Remy Mickel (minor)

Ross Mickel

Luke Ludwig

Rebecca Ludwig

Joanne Mera

Gabrielle Hanna

The deceased individual recovered from the water on Sunday night was transferred to the Island County coroner and has not yet been positively identified. It is Coast Guard policy not to release the names of the deceased or missing until at least 24 hours after the next of kin have been notified.

“The Coast Guard offers its deepest sympathies to those who lost a loved one in this tragedy,” said Cmdr. Xochitl Castañeda, the Search and Rescue Mission Coordinator for this incident.

The National Transportation Safety Board is conducting an investigation into the accident.

-USCG-

ADS-B data shows a sudden plunge from cruise. Happened very quick. Something apparently caused a quick dive.

ReplyDeleteCable failure

DeleteThe previously famous Otter elevator up cable?

DeleteThis is a good discussion of the Otter cable issue, with images:

Deletehttps://admiralcloudberg.medium.com/the-crash-of-air-moorea-flight-1121-analysis-4cbc6ea283d3

Investigation report of the DHC-6 Moorea crash is at this link:

Deletehttps://bea.aero/fileadmin/documents/docspa/2007/f-qi070809.en/pdf/f-qi070809.en.pdf

Is it possible that the pilot had a heart attack or brain hemorrhage? My niece uses Kenmore Air all the time from Friday Harbor to Paine Field

Deletesadly, RIP.

ReplyDelete7th leg of the day. First was @ "Time: 01:56:37 Z,"

ReplyDeleteaccident 7th leg @ "22:08:53 Z." Two previous flights 5 and 6 minutes. For what purpose?

Previous day 4 legs.

The San Juans had the shortest airline scheduled route between two islands for years.

DeleteIt's common to pickup and drop off passengers at private docks in addition to the normal seaplane bases. I've been on flights where the pilot used a high-speed water taxi between docks a mile or two apart.

DeleteAll those little strips in the San Juans are super close so 5 min flight segments make sense, especially for this charter.

ReplyDeleteI was just up there last Sunday and we hit Friday, Lopez and East Sound. I think Friday to Lopez was 3 min flight time.

anyone know if an Otter has a zero fuel weight and what is the maximum payload?

ReplyDeleteRIP to those perishing in what should have been just another short flight. Hopefully NTSB will determine cause.

ReplyDeleteAs of Sep. 5, 2022 at 1:39 pm PDT the Times is reporting the Coasties have suspended the search, no survivors expected. Condolences to the people who had to inform the families of their loss. :(

ReplyDeletewonder how many total float plane rotations, and since 2018 with 'Owner, NORTHWEST SEAPLANES INC. 1967 DEHAVILLAND DHC-3, Fixed wing single engine(11 seats / 1 engine)"

ReplyDeleteExactly what is a float plane rotation? And why would they only be relevant since 2018 and not the life of the aircraft?

Deleterotation .. take-off and subsequent landing, the two most critical aspects of any flight.

DeleteCycle = takeoff + landing.

DeleteRotation = pitch-up during the takeoff run.

Sudden descent sounds similar to Chalk Airlines older seaplane crash in Florida where a wing broke off due to corrosion on aluminum wing spar from salt water after many repairs for cracks in same area as break of main wing spar. How deep is water at crash site? Hopefully plane can be recovered to inspect for wing failure. Or perhaps a big seagull or goose hit windshield and incapacitated pilot. Plane had Turbine engine which is very reliable. Think plane was built in 50s. Company had been flying for about 24 years .

ReplyDeleteLooking at the depths in the approximate crash area of Mutiny Bay, it is in about 150 feet of water, +/- 50.

DeleteSalt water corrosion could explain many possibilities, such as the wing failure in the Chalk accident. Would also consider horizontal stab or elevator failure (spontaneous, load-induced, or bird-strike). What about cabin floor collapse into the control cables?

Once they surface the wreckage, it should be straightforward to determine cause. Not many things would cause a sudden plunge.

Two historical instances of in-flight DHC-3 elevator servo tab (trim tab) problems in CAROL, with the N3125N incident including uncommanded nose down pitch:

DeleteN3125N Report:

https://data.ntsb.gov/carol-repgen/api/Aviation/ReportMain/GenerateNewestReport/89350/pdf

N3125N Docket:

https://data.ntsb.gov/Docket?ProjectID=89350

N3125N Docket's Airworthiness Group Factual Report:

https://data.ntsb.gov/Docket/Document/docBLOB?ID=40445890&FileExtension=.PDF&FileName=Airworthiness%20Group%20Factual%20Report-Master.PDF

N3125N Docket's Airworthiness Group Factual Report Photos:

https://data.ntsb.gov/Docket/Document/docBLOB?ID=40445891&FileExtension=.PDF&FileName=Airworthiness%20Group%20Factual%20Report%20-%20Appendix%20A%20-%20Figures-Master.PDF

N472PM (1995) Report:

https://data.ntsb.gov/carol-repgen/api/Aviation/ReportMain/GenerateNewestReport/2685/pdf

You can't live very long in the Pacific Ocean. Even in the summer, hyperthermia sets in quickly. And it's very deep in that area -- over 600 feet.

ReplyDeleteN725TH's sister ship, N703TH, formerly under the same ownership, pitched over uncontrollably in level flight and crashed near Yakutat, Alaska last May.

ReplyDeleteThe description of how N703TH behaved has similarity to the N3125N and N472PM elevator trim tab incidents:

Delete"While enroute he stated that the tail of the airplane seemed to move up and down which he attributed to turbulence."

N703TH Prelim:

https://data.ntsb.gov/carol-repgen/api/Aviation/ReportMain/GenerateNewestReport/105132/pdf

Given that the aircraft hit the water in a nose dive at well over 100 mph I doubt that water temperatures would pose much of a problem. RIP.

ReplyDeleteSeems like that plane model should have been grounded since many other same model have had problems with elevator trim

ReplyDeleteBy this standard every car, bike, atv, etc should be removed from service. They mad several hundred otters and they have all been in service for 60 plus years. A handful of incidents is not a reason to cease operating.

Deleteyeah.....but ATVs and cars don't fall out of the air. Wake up.

DeleteThe Beavers were designed for bush flying into Canada back woods with fresh water lakes not harsh salt water environment

ReplyDeleteThis was an Otter, not a Beaver. But both have been in service in saltwater environments for decades, with proper maintenance saltwater isn't a problem.

Deletelol...yeah "seven decades in a salt water environment" no thanks sir, I'll just swim.

DeleteWood rots, steel rusts, (fiber)glass breaks, carbon snaps but aluminum tends to "evaporate".

DeleteIt was noted that on floats, the airplane's tail was approximately 10 to 11 feet above the ground and very difficult to examine during preflight (See N472PM (1995) Report).

ReplyDeleteSmoking rivets and crack development that gets underway after the most recent 100 hour inspection can be detected if an up close preflight look is made at least once each multi-hop ferry day.

Operators should be able to swing the tail over the dock and do a ladder supported preflight of the tail surfaces at the start of the day. Being on floats is no excuse for skipped preflight examination that would catch ongoing trim tab crack progression, if that is what occurred here.

You are assuming the the point of failure was external and not internal. The trim tab control mechanism in these aircraft is not entirely visible.

DeleteDark trails from smoking rivets were present and visible for many hours on N3125N, viewable in docket photos. The comment was to not skip the pre-flight examination for similar, didn't comment on point of failure.

DeleteI thought they traced the 25N failure to recent MX. Guess I should go back and reread that NTSP docket

DeleteI believe this operator and the Kenmore Air fleet are stored on land at the end of each day

DeleteAvailable ADS-B data show a speed reduction shortly before the mishap. Of various possible causes for this, one is pilot reaction to onset of flutter caused by trim tab failure. The pilot of another DHC-3T aircraft reacted to trim-tab-induced flutter by reducing speed, and landed safely. The pilot of N725TH wasn’t as lucky, whatever the cause.

ReplyDeleteRemember: a sudden high-speed dive would also show as a “speed reduction”, since the displayed ads-b speed is only the horizontal projection of true airspeed.

DeleteTrack data gives ground speed, from transmitted GPS coordinates.

DeleteThe poster is correct in that the ground speed reduced without loss of altitude during the 20 seconds before the plunge started:

https://globe.adsbexchange.com/?icao=a9b7d0&lat=47.997&lon=-122.594&zoom=14.5&showTrace=2022-09-04&leg=7&trackLabels

The bay itself is shallow and up to 120’ on the edges. Lots of current however will make this recovery trickier than a lake recovery.

ReplyDeleteADS-B Replay for the time period doesn't find any other aircraft nearby in a position to have observed the crash. N50KA DHC3 flew straight over the crash location at 22:15Z (about six minutes after the crash) and a search helicopter shows up starting to orbit the crash location at about 23:02Z.

ReplyDeleteReplay (Hit pause, reduce speed from 30x, play):

https://globe.adsbexchange.com/?replay=2022-09-04-22:07&lat=47.995&lon=-122.609&zoom=12.3

Dan thinks elevator corrosion from salt water caused elevator to fail causing nose to pitch down based on 3-4 other crashes of same model plane caused by elevator failure due to corrosion from salt water. Seems like pilots would demand a ladder be available for every preflight inspection. Victims Lawyers will love this video. This appears to have been a preventable crash. Wonder why NTSB did not recommend a AD or daily inspections of elevator in the NTSB reports on other 3-4 crashes. FAA should have issued an AD on elevator on this model.

ReplyDeletehttps://tc.canada.ca/en/aviation/reference-centre/civil-aviation-safety-alerts/service-difficulty-alerts/havilland-dhc-3-service-difficulty-alert

Deletehttps://www.tsb.gc.ca/eng/rapports-reports/aviation/2019/A19C0138/A19C0138.html

DeleteThe first tc.canada document describes reports of wear on a push / pull rod produced by rollers that weren't checked and maintained in a free wheeling condition.

DeleteThe second tc.canada document describes a fatigue fractured lug in the wing strut connections. The Canadian AD CF-2020-20 came across under the bilateral agreement to become an FAA AD, (starts at the bottom of the first page, here):

https://www.govinfo.gov/content/pkg/FR-2021-12-20/pdf/2021-27409.pdf

To the original poster who clicked on the monetized tuber video, what are the N-numbers or NTSB numbers of the elevator failure crashes alleged to be due to corrosion from salt water?

https://www.youtube.com/watch?v=9vQJ6T9wmyM

DeleteFrom a pilot's perspective.

It’s not about money. It’s about lives. I’m sure everyone was doing their best in regards to the inspections. Who knows maybe birdstrike . Money does not replace lives futures loved ones

DeleteWhat is the likelihood that pilots of float planes diligently inspect the tail surfaces before each short hop? That would entail swinging the tail over the dock, climbing a ladder, moving the surfaces and servo tabs by hand and looking for free play buildup, wear or other change in condition.

DeleteFlutter is oscillation. Built up wear and yielding sets up for flopping back and forth, the layman's term for oscillation. Doesn't take long for oscillation to "work on" the already floppy condition and proceed to failed linkage rod connections and torn away surfaces described in prior reports.

Nobody admits it, but a quick turnaround after a short hop can be expected to omit making close up tail inspection or the "floppy surface check" before going up again. Preflight check may only consist of "looks like it's all still there" from a distance.

Easy to see this accident happening if you go up and servo tab flutter due to the detectable condition you didn't check for causes one of the exact failures seen previously.

Chalk Airlines crashed due to metal “fatigue” crack on wing, not salt water corrosion. FAA was partially blamed for approving maintenance even though Grumman the manufacturer had issued a warning that fuel leaks could be sign of serious wing metal fatigue problems. The DHC-3 elevator problems may not be related to salt water corrosion but extreme vibration of tail during take off and flight in prop wash. Black marks around rivets on DHC-3 elevator were known to be sign of movement of rivets coming loose . Both the Chalk Grumman’s fuel leaks and the several DHC-3 known elevator problems should have been signs of pending failure. Chalk was in bankruptcy maybe skimping on maintenance. . Small privately family owned operators of DHC-3 may not be making huge profit and skimping on maintenance .

ReplyDeleteUnfortunately, not a large enough fleet to have the data to know the highest risk, and not enough money to spend on anything the regulators don’t mandate.

ReplyDeleteStepladder pricing is not high enough to prevent the PIC from bringing his own to the job if Mom and Pop and the A&P can't afford one. Haul the ladder on your pickup truck rack to your next job if you get fired for inspecting the tail every day using your own ladder.

Delete? Uncommanded beta pitch after power reduction

ReplyDeleteuncommanded elevator trim ???

ReplyDeleteThis accident will be difficult to assess a probable cause

All trim and control inputs are manual cable connections in the otter

DeleteIf a wing broke off the wing would be floating on the surface. Something else happened. Dan might be onto something.

ReplyDeleteAn explosion that sounded like thunder, as reported by one witness, is not a wing failure or water impact. It is an explosion and must be investigated. Accidental or intentional must be determined. The one body recovered may show clues but recovering the aircraft will be the best evidence.

ReplyDeleteI beg to differ. An airplane or any large object impacting the water at high speed makes a loud noise like an "explosion" does (a sudden unexpected noise). It is not like an Olympic diver entering the water. Whether it "sounds like" thunder to someone is irrelevant. There is no reason to believe there was a bomb. If a bomb, it would have occurred with the plane in the sky, not hitting the water and there would be lots of debris on top of the water, which was not the case.

ReplyDeleteAn explosion at 900' MSL would create a smoke marker at that height that witnesses would comment on.

DeleteThe witness who turned to look after hearing the sound reportedly saw the post-entry water splash. That witness would have turned and looked before the falling aircraft made it to the water if the sound came from a bang in level flight at 900 feet.

Think it's time to look at the STC for the turbine engine conversion and examine it for airframe related tests proving no undue airflow related and/or power-plant related fatigue causing vibrations within the empennage and extreme aft fuselage area. NTSB records suggest this might be a good idea since this appears to be the fourth event that turned fatal.

ReplyDeleteChanging the power-plant, propeller and position of the power-plant on an airframe can often create new and sometimes damaging stresses upon it and/or its components.

Read about the 2003 initiative on that exact subject, linked below. Searching on DHC-3 elevator in https://drs.faa.gov/search will find lots of servo tab related actions over many years.

Deletehttps://drs.faa.gov/browse/excelExternalWindow/54F39EEA6833D1E086256DD50057D5D5.0001

That AD interestingly appears to possibly not apply to 725TH that had the Walter M601 conversion. (Looks like it applies to the P&W PT6A-34 et al). I also noticed on Airliners.com someone posted a photo of 725TH and the caption read "Walter Conversion Prototype". The sister aircraft 703TH also allegedly had what sounds to be a servo tab problem in the past and also has the Walter M601 conversion.

DeleteLinking one of the past documents related to turbine conversions was only intended to show that the "time to take a look" original post was not considering DHC-3 history of actions related to elevator and servotab issues. There are a lot of past servo tab and substitute STC parts "actions" when you dive in and look. Digging in may find the Walter documents as well. Too many make comments without reading the Tahiti investigation report or opening any other provided links. You did good by looking closer.

DeleteWhen I was in Tahiti in the summer of 2007, there was a twin Otter crash during the flight from the island of Moorea to Tahiti. The investigation said an elevator problem caused the crash. Maybe an issue with salt water corrosion?

ReplyDeleteWorn cable in a DHC-6, full report w/pix is here:

Deletehttps://bea.aero/fileadmin/documents/docspa/2007/f-qi070809.en/pdf/f-qi070809.en.pdf

Just finished reading the Tahiti report - it's a heck of a document and contains some very thorough work and investigation of cable wear issues and failures as related to cable material (stainless vs carbon). Well written, and worth reading.

DeleteOn 22 December 1997, Transport Canada issued supplementary type certificate (STC) n°SA97-124 to Thunder Bay Aviation in relation to replacement of carbon steel or stainless steel control cables on the DHC-6-100,-200,-300, DHC-3 and DHC-2 aeroplanes. This STC allowed the company to sell its cables directly as a replacement for the original De Havilland cables. The Thunder Bay Aviation stainless steel control elevator control cables were identified with the references TB-EO 69053-1 to TB-EO 69053-5

ReplyDeleteControl cables required to be replaced “every year” in salt water environment on the DHC-3 plane.

Tail elevator visual inspection required before each flight on a preflight

Both types de cables can be installed: carbon steel or stainless steel. These cables are qualified according to the specifications of standard MIL-W-83420.

ReplyDeleteTheir normal life span is five years but their utilisation in a saline atmosphere is limited to one year.

I do not know anything about the cable routing, loading, pulley radii, or other technical aspects of any of the control systems used in a DHC-6, but I will categorically state that stainless steel cables have much lower fatigue resistance and minimum radius capabilities than high carbon steel cables. Many years ago I purchased the remains of a 1940's light airplane where the original carbon steel rudder cables had been replaced with stainless cables. At a point where one of the cables ran over a fairly small diameter pulley, 5 of the main cable bundles of the 7X19 cables had completely separated, leaving only 2 intact, which were almost certainly rather compromised as well. (This was unrelated to the cause of the crash, It was just an existing condition that I happened to discover during disassembly.) Since this observation, I am generally not a big fan of stainless cables. I would have concerns about any stainless cables used as replacements for original carbon steel cables, regardless of the approval methodology used by any supplier other than the original manufacturer.

DeleteQuick maintenance logbook check could determine if control cables had been replaced every year as required by AD . Logbooks should be kept in maintenance office so logbooks are not lost in crash

ReplyDeleteDoes anyone know if there are grommets in the holes in the metal that contain the cables? There are all sorts of hard plastic or ceramic materials that could minimize friction.

ReplyDeletePolyamide (plastic) cable guides are what caused the wear on the cables in the famous Tahiti DHC-6 crash. See photo of those plastic guides on pdf sheet 38 (Document native page 36) in the official report:

Deletehttps://bea.aero/fileadmin/documents/docspa/2007/f-qi070809.en/pdf/f-qi070809.en.pdf

I think they should do more than mandating periodic cable replacement using the same cables. Doing a search, there are differences between synthetic rope and steel cable that seem to favor the lower loads/stresses encountered in a smaller airplane:

ReplyDeletehttps://winchmania.com/synthetic-rope-vs-steel-cable/

I was just speculating, but stand corrected. Thanks for the specific information about the grommets (bushes). I hope they don't use stainless steel any longer....

ReplyDelete"A range of wear appeared on the stainless steel cable whereas no wear was detectable on the carbon steel cable."

And the appendix of the report also includes survey results that reveal how the removed carbon steel cables of Otters operating in saline environments removed on schedule weren't exhibiting much evidence of corrosion.

DeleteOn the synthetic rope comment - An aircraft making an emergency descent after indication of smoke or fire can't afford the risk of taffy pull melting or melt through of synthetic flight control cables. Fine for a winch drum on a jeep, though.

Has anyone considered the ADSB ground speed registered up to 150 mph before the crash? I flew this same day in a 172 two hours before the accident and about 6 mi south of the accident site. It was turbulent with winds 15 to 20 mph. It was tough to keep my 172 level and I reduced speed to Va. If his ground speed was 150 mph, he was already above VNE. Forget about Va.

ReplyDeleteI will note, winds were from the south on 9/4/22. Crash occurred while flying SE from KFHR to KRNT.

DeleteThat's a great picture of Jason -- intense focus with his hand on the throttle. I bet he was really cool guy and great seaplane pilot.

ReplyDeleteSo sorry to hear about this terrible loss.

The water depth at the crash site is reported to be (1) 100 feet, (2) 3-400 feet, (3) 500 feet. Which is it? Is there going to be any attempt to raise this Otter and attempt to locate what's left of the bodies? Or ... is this going to be considered Burial at Sea? Anyone with any info on this?

ReplyDeleteYou sound like you'd be real fun to sit next to at a funeral...sheeeeesh...

DeleteThe poster was merely asking a simple question ... don't think they were out of line by any means. There has been no info on recovery efforts.

DeleteIt has been confirmed that the depth of water at the crash site is 205 feet.

DeleteDoes the depth of 205 ft. rule out any recovery efforts?

DeleteYou can check out the depths in that area on this chart...

ReplyDeletehttps://www.charts.noaa.gov/OnLineViewer/18440.shtml

Mutiny bay is 48N and 122 35W.

Comments

ReplyDelete|

6

Share

SEATTLE (AP) — The wreckage of a floatplane that crashed into the waters of Washington state’s Puget Sound last week has been found on the sea floor, The National Transportation Safety Board said Monday.

The NTSB said the depth and motion of the water hid the wreckage for several days, The Seattle Times reported.

Sonar located a “large section” similar in length and width to the plane about 190 feet (58 meters) below the surface of Puget Sound near Whidbey Island, according to spokesperson Jennifer Gabris.

Investigators, the National Oceanic at Atmospheric Administration and the University of Washington’s Applied Physics Laboratory scoured a 1.75-by-0.75-mile (2.8-by-1.2 kilometer) area where witnesses said the plane had crashed.

Because of the depth and 3-5 knot currents, the NTSB is seeking a remotely operated vehicle to recover the wreckage. The NTSB had said that crash details, including the cause of the crash, couldn't be determined until more of the wreckage was found.

Ten people were on the Sunday flight from Friday Harbor in the San Juan Islands to the Seattle suburb of Renton when it crashed on Sept. 4. The only body that has been found was identified last week as Gabby Hanna of Seattle.

Remotely operated vehicles versus human divers:

Deletehttps://www.deepbluediving.org/maximum-depth-with-gear/

News says plane has been located by sonar . Next will be finding way to recover plane. Then the cause can be determined and inspections of same model can be completed to prevent more crashes . Seems like FAA would issue an AD to require elevator inspections since there have been 3 crashes of same model due to elevator problems per NTSB reports.

ReplyDeleteLocating a major portion of the fragmented plane by ROV is a start, but recovering everything NTSB needs in order to be certain of exact cause will be hit or miss with currents moving the pieces around at depths.

DeleteMeanwhile, the aircraft operators don't need to wait for official direction. It is a straightforward process to go do a detailed condition inspection for each of the possible circumstances that have already been documented.

When your customers ask about your aircraft from their concern about this crash, relating that those detailed inspections were done on your own initiative without waiting is the correct response.

The NTSB reports for the events occurring at, Ketchikan AK, 1995; Homer, AK, 2014; Skwentna, AK, 2015; Yakutat, AK, 2022, all pointed to the elevator trim-tab system as being the main culprit for the events. Lombadina, Austrailia, 2008 follows suit. These trim system problems have been occurring since about 1968 (Sarasawa Air Base, India, 1968) on the Otter series airplane whether they're equipped with a recip. of turbine power plant. This suggests an airframe-power plant-propeller pairing problem. Hope the NTSB ASI will catch this and thoroughly investigate the issues, if any.

ReplyDeleteBased on information obtained, it appears as though the servo tab is subjected to harsh vibratory environment due to natural airframe vibrations and spiraling slipstream impacting the empennage. The reported damage within this area appears to be consistent with aerodynamic flutter of the elevator servo tab to the point of imposing serve loads upon it and elevator spar structure. Airspeed, spiraling slipstream and inadequate airframe stiffness can result in a servo tab flutter and ultimate failure.

With some STC'd Otters using various types of turbine engines the propellers are larger than the airplane was originally certificated with. This may create greater turbulent air volume and spiraling slipstream forces acting upon the empennage which adds more stress to it's components. One has to ask, how were these STC's designed and tested for safe operations on the DHC-3? Who certified and approved the STC? Did the approving agency conduct their own testing (normally they use the applicant's test data)? Did anyone do an analysis of the forces acting upon the empennage with the new power plant-propeller-air frame pairing?

A Canadian accident report stated, "The DHC-3 Otter has a history of tailplane flutter; however... a reduction of power and airspeed at the moment of onset of flutter vibration prevented further flutter vibrations... ." There are Canadian and FAA AD's regarding airspeed limitations on the DH C-3. On 09/26/2000, an STC was issued for a Flutter Prevention Modification kit. The accident reports I've read do no indicate the installation of the kit on any of the affected airplanes.

On 03/01/2004, the FAA issued an AD, Docket number, 2000-CE-73-AD which prohibited airplane operations unless a new STC for an elevator servo-tab with a redundant control linkage is installed on turbine powered DHC-3 airplanes. Another FAA AD effective 03/31/2011, requires repetitive elevator control tab inspections for discrepancies. Were these complied with? The Canadians issued an AD, CF-08-13, that deals with elevator tab flutter; also CF-85-04, elevator push-rod inspections and CF-89-20R1 for tail-plane rib cracking. Their AD, CF-2006-02 suggests there are additional spiraling slipstream (maybe whirl mode flow?) problems with the DHC-3T airplanes: "For all DHC-3 Otter aircraft retrofitted with a turbine engine-- install Viking Air Ltd. flutter prevention kit V3MK1148 Issue 3 or equivalent. (effective date- 03/31/2008)" Presuming a loss of control because of the elevator trim system failure, did the latest DHC-3 that carried 11 souls to their maker have such a kit?

Based on my limited review of the information available it appears as though this long-standing problem has been addressed from logical angles. As the one FAA AD stated,"The failures [of the servo tab] were attributed to the increased velocity and airflow over the servo tab caused by the turbine conversion." My question is- Why'd this happen with the recip versions of the Otter then? Could this be a basic design problem that has been bandaged for as long time? One that perhaps was made worse by the turbine engine and larger propellers greater aft flow volume?

The NTSB ASI has a very interesting case before him. Let's hope and pray he'll solve the problem, issue a good safety recommendation to the FA and the FAA produce a sensible AD that'll ultimately prevent more good people from dying.

One cause of servo tab flutter failure was evident back in 1995.

DeleteAn operator was skipping servo tab pre-flight checks. Can't detect that the tab and mechanism is damaged or wearing toward excessive free play that will flutter if you don't put a hand on it back there and manipulate it during pre-flight.

Operator in the 1995 incident stated that the airplane's tail is approximately 10 to 11 feet above the ground and is very difficult to examine,

Did accident aircraft N725TH get a hands-on-tab wiggle check between the beginning of it's day and the accident leg takeoff, or just one check before the first flight of the day? What does the company flight operations plan require?

N472PM (1995) Report:

https://data.ntsb.gov/carol-repgen/api/Aviation/ReportMain/GenerateNewestReport/2685/pdf

I am a former airline Captain and flight instructor . My daughter and I flew on a Chalk Airlines Grumman Mallard In 1995. 10 years later in 2005 a wing broke off a Chalk Mallard due to metal fatigue that it’s FAA inspector should have known about but signed off on the safety of Chalk’s planes.

ReplyDeleteA couple of years ago my son and his wife flew in a Key West Seaplane Tours DHC-3 plane from Key West to Dry Tortugas . My son was a solo pilot at 16.

My son and I both took flights on seaplane models that later crashed due to maintenance issues that could have been prevented .with proper FAA oversight . We assumed the charter companies were conducting proper maintenance. We were lucky the planes we flew on did not crash.

I have been a pilot for companies that that knowingly did not do proper maintenance to save money or knowingly made pilots fly with illegally long duty days with short rest periods. The FAA did nothing to stop the illegal flights that I reported to FAA .

Hansen Helicopters in Guam and its owner and its FAA inspector were recently found guilty of criminal charges due to serious maintenance violations .

Until the FAA starts enforcing its rules, violations of FAA rules and crashes will continue.

The alphabet FAA is another corrupt agency ... no better than the FBI, et.al. As a pilot, I personally have had horrible experiences with the FAA.

DeleteOh, that's too bad. It sucks to be you, Dan.

DeleteGive Dan a break … he can’t help himself.

DeleteThis was from 2004:

ReplyDelete"This AD is the result of reports of the control rod to the elevator servo-tab system detaching from the elevator servo-tab, which caused the elevator servo-tab to flutter on airplanes with a turbine engine installed."

https://www.federalregister.gov/documents/2004/03/01/04-4373/airworthiness-directives-bombardier-inc-model-otter-dhc-3-airplanes

There are electronic versions of the Otter to use with Flight Simulator:

ReplyDeletehttps://www.justflight.com/product/dhc3-otter

Sure am glad to see that no readers make ad hominem comments:

ReplyDelete"Attacking a person's character or motivations rather than a position or argument."

Locating and recovering detached control surfaces of the impact-fragmented aircraft may be severely impeded by the depth, dispersal by current and low visibility. Probably requires an extensive ROV camera search of the bottom on a grid pattern after the cabin section is raised to have any likelihood of recovering investigation relevant elevator and servotab pieces..

ReplyDeleteTurbidity might make camera observation ineffective for distance of more than just a few feet away while lit with spotlights. A manned submersible with manipulator arms might be required for effective parts search and pickup.

Wether or not we like it it would be good to have a BRS on all smaller planes used for part 135 ops. It's about the well being of passengers not some macho attitude. If a control cable breaks or some latent mechanical issue happens like the whole stabilizer off little the best pilot in the world could do. Even with adherence to the strictest maintainance standards there's always drones in the air that can rip a wing off or even a midair.

ReplyDeleteA noble quest, but no aircraft with PAX capacity of an Otter has BRS right now and no STC exists to add one. Even as aircraft with BRS may become available in the future, cost constrained tour operators will still be using older aircraft that won't have the chute for years afterwards.

DeleteMajor liability insurance reduction for 135 operators would do it since they pay tens of thousands if not hundreds of thousands per year. Commercial airplane insurance is expensive and if made even half as expensive with a BRS on the plane, and the elimination of the deductible if the chute is pulled like it is done for Cirrus, this could be quite the incentive. Since the rebate would be like 50-100k and pay the chute!

DeleteSeems unlikely that incorporating BRS in a future new design Otter would reduce the liability insurance cost by half, since so many sightseeing floatplane crashes are CFIT. Some price reduction for commuter route flyers might be possible, but actuarial tables factor in water landing mishaps and crashes immediately after takeoff, which like CFIT are risk exposures that BRS won't reduce.

DeleteHow can anyone be sure that the numerous repairs/part replacements that were done just days before the crash were done correctly? Is another qualified maintenance person required to double-check those actions? I don't know.

ReplyDeleteThe airplane’s most recent 100-hour inspection was performed on September 1, 2022. Included at that time were recurring inspections required by Airworthiness Directives (AD) 83-04-05 (control column lower assembly) and 2011-18-11 (elevator control tabs). A left-hand rudder retract cable was replaced during the 100-hour inspection. The previous 100-hr inspection was performed on August 16, 2022, which also included the recurring AD inspections noted above. At that time, the horizontal stabilizer hinge bolts, a right-hand engine ignitor, and a left-hand float locker latch were replaced.

It is interesting to notice that per AD 2011-18-11 Action #3 detail, FAA notification is required if during inspection the total maximum free play of the elevator servo tab and trim tab relative to the elevator exceeds 1.0 degree (this is equal to a maximum displacement of 0.070” at the trailing edge).

ReplyDeleteLess than a tenth of an inch!. If you aren't hands on preflight checking for that before every takeoff, there is no assurance that your next leg won't be subject to the known flutter condition, even on the second leg of the first operational day after the 100 hour check.

AD 2011-18-11 link:

https://drs.faa.gov/browse/excelExternalWindow/A12CA90E8912318A862578FB0046E92D.0001

Is there any news as to the status of the recovery of the fuselage and other parts of the wreckage?

ReplyDeletePlanning for 26 September after getting resources in place:

Deletehttps://www.kiro7.com/news/local/effort-raise-floatplane-wreckage-off-whidbey-island-begin-sept-26/XT7O7HM5KZFQXFNF44HJGG3OXU/

Looks like they may be out on this Tug now with the ROV based on its track.

Deletehttps://www.marinetraffic.com/en/ais/home/shipid:436864/zoom:14

Official update on 9/27/2022:

Deletehttps://www.ntsb.gov/news/press-releases/Pages/NR20220927.aspx

Engine has been recovered:

Deletehttps://twitter.com/NTSB_Newsroom/status/1575641446584942592

It appears progress is being made...

ReplyDeletehttps://www.msn.com/en-us/news/us/bodies-of-floatplane-passengers-80-of-wreckage-recovered-off-whidbey-island/ar-AA12pq9D?cvid=3720a12da9d040fdd39b1b1877af5fda&ocid=winp2sv1plustaskbarhoverent

Video with NTSB here:

ReplyDeletehttps://www.king5.com/article/news/local/passengers-recovered-floatplane-wreckage-whidbey-island/281-772a99de-3a65-478f-95f5-5016ec3f036f

Familie's attorneys should ask two preflight inspection questions:

ReplyDelete1. Was a hands-on free play check for 1/10th inch done each op day?

2. Was that hands-on free play check also done before each takeoff?

After this accident, passengers boarding any DHC-3 should also ask these questions, particularly if NTSB never finds those missing elevator parts.

Another thing to consider with a plane like this is pilot incapacitation. Its my understanding that the controls on the right side have been ripped out; so if something happened to the pilot at 1k ft AGL, you would have to get the pilot out of the seat, then get in the left seat to gain control.

DeleteHonestly, I would never fly in an airplane that 100% depended on 1 person. That's where I would end my pre-flight inspection and walk away...

Most likely this AD is in response to this crash:

ReplyDelete"This Emergency AD was prompted by multiple recent reports of cracks in the left-hand elevator auxiliary spar."

https://drs.faa.gov/browse/excelExternalWindow/DRSDOCID139391948320221005002535.0001?modalOpened=true

AD: 2022-21-51

Story continues here:

ReplyDeletehttp://www.kathrynsreport.com/2022/10/de-havilland-canada-dhc-3t-turbine.html

From a recent article. MY kind of pilot! No screwing around, full attention (about Jason Winters). Nobody can overcome a broken elevator close to the ground:

ReplyDelete"When he was flying, he was a completely different person, Miller said. No joking, barely any smiling. After flying with Winters numerous times, Miller has told people if he is ever “going into a bad situation or bad weather, whether it’s driving a car or plane or boat, I’d want [Winters] behind the wheel.”

This is a very good explanation of the elevator and horizontal stabilizer and what may have gone wrong in the de Havilland Otter with lots of images!

ReplyDeleteIt appears the cause has been identified: a missing or improperly installed locking ring — a wire that’s supposed to prevent the elevator actuator end from unscrewing — allowed the control attachment to come off the actuator drum. The aircraft became instantly uncontrollable in pitch, and nosed down from loss of the normal downward force of the horizontal tail.

ReplyDeleteIt looks like an emergency AD is imminent.

Never mind, found it.

ReplyDeleteInvestigators found the horizontal stabilizer actuator, which is part of the airplane's pitch trim control system and is also referred to as the trim jack, had separated into two pieces," the agency said.

ReplyDeleteThey concluded those pieces separated by unthreading, not by being pulled apart. The safety board also explained that investigators were unable to locate a locking ring that holds the two pieces in place.

https://sanjuanislander.com/news-articles/government-news/federal/35236/missing-wire-lock-ring-may-have-been-cause-of-sept-4-float-plane-crash

ReplyDelete