The Carrs are one of nearly two dozen families that have taken advantage of Greater Bemidji’s 218 Relocate program, which offers incentives to those who move to Bemidji and work remotely. Tony is a geospatial technician for Boeing, creating flight charts for commercial airline pilots. They moved from Denver with their two young daughters in June, and are living with Sharon’s parents on Lake Movil until December 14 when they close on their new home.

Tony and Sharon Carr are pictured with their daughters Madalyn, 4, and Loralee, 7, on November 22, 2021, in Bemidji. The Carrs are one of nearly two dozen families that have taken advantage of Greater Bemidji’s 218 Relocate program, which offers incentives to those who move to Bemidji and work remotely.

~

BEMIDJI, Minnesota -- After a near-fatal plane crash, every day is Thanksgiving for Tony and Sharon Carr. But this year they’re also thankful for a new town, a soon-to-be new home and a relocation program that helped make it all happen.

“We’re always thankful,” said Sharon Carr, who grew up in Bemidji. “It’s definitely fun being back home. There’s no place like Bemidji.”

The Carrs are one of nearly two dozen families that have taken advantage of Greater Bemidji’s 218 Relocate program, which offers incentives to those who move to Bemidji, Minnesota, and work remotely. Tony is a geospatial technician for Boeing, creating flight charts for commercial airline pilots. They moved from Denver with their two young daughters in June, and are living with Sharon’s parents until Dec. 14 when they close on their new home.

When Tony learned about 218 Relocate, he did a double-take.

“That was exactly what I was looking for,” Tony said. “My company was not going to reimburse, because it was an optional move. I saw a commercial for it on TV and said, ‘Was this commercial made for me? Was it targeted toward Tony Carr?’ Because this seems like a perfect fit when you’re looking at helping people who are able to telecommute move to the Bemidji area. There also was the draw of the fiber-optic network here.”

A love of flying

Tony grew up in Houston and became interested in aviation at a young age.

“Going to the airport was always kind of a highlight,” he said. “I really enjoyed just being on the plane and being able to see everything from above. The bug kind of caught me early that I wanted to do something in aviation.”

He attended Oklahoma State University and earned an aviation science degree while also working as a flight instructor. After graduating in 2008, he was a flight operations intern for Mesaba Airlines, which flew into Bemidji. That’s when he met Sharon.

“He was up here visiting,” she recalled. “He got a jump seat pass on a flight to Bemidji. For whatever reason, he wanted to see more of Minnesota.”

Sharon was at McDonald’s on a break from work. Tony just happened to be at the same place.

“He bumped into me and ended up spilling a drink on me,” she said with a grin. Then he asked for her phone number. She said no. Then he asked for her email address.

“He said, ‘Let me just email you. So if you don’t like me, then you don’t have to respond.’ I soon realized he’s such a good writer. So it started off as emails and kind of went from there.”

After Tony left Mesaba that summer, he returned to Oklahoma State to do more flight instruction. For the next two years, he and Sharon had a long-distance relationship, with visits back and forth from Bemidji to Oklahoma.

Moving east, surviving a crash

Tony got his first full-time job as a pilot in 2011, delivering cargo for AirNet Systems, a subsidiary of FedEx. He was based in Richmond, Virginia, and made overnight flights up and down the East Coast. Sharon joined him in Virginia, and the couple set a wedding date for December 2011.

“It was interesting flying because it was all at night,” Tony said. “But it started to take a toll on me with the interesting hours and just missing out on things because of the weird schedule. I really liked flying but it was getting a little old. Sharon and I had not started a family yet, but we were looking in that direction, so it was going to be a challenge for us if I stayed in this job.”

On April 11 of that year, everything changed.

Tony’s flight that evening was headed to Charlotte, North Carolina. As he was taking off from Richmond International Airport, one of his engines quit working after takeoff. The plane crashed back down over the runway.

“I was knocked unconscious and because of the impact obviously the plane was up in flames,” he said. He suffered burns over 60% of his body.

“Luckily the airport fire and rescue was located in the middle of the airport and they were able to get to me pretty quickly,” Tony said. He was taken to nearby Virginia Commonwealth University Hospital, which just happened to have an official burn unit.

“After that initial engine failure happened, a lot of things were really lining up favorably,” he said. “I was kept in Richmond unconscious for a couple of months in a medically induced coma, and stayed in the hospital for another couple of months before I was able to go home.”

For the next three years, Tony endured nearly 70 surgeries and all kinds of physical and occupational therapy.

“Most of my time in Richmond, unfortunately, wasn’t spent working,” he said. “First it was about trying to keep my body alive, then giving me the functional ability to live, not just to survive but actually to be somebody who could live a life.”

Sharon’s full-time job during that time was taking care of Tony and getting him to and from appointments and surgeries. They changed their wedding plans and decided to get married on September 10 in Virginia.

“It was on 9-10-11, so that way you can never forget it,” Sharon said. “He still was in therapy. So I have my wedding dress in one hand and this huge duffel bag with all of his wound care in the other. I definitely did my fair share of wound care.”

Deciding what’s next

Tony figured he would never be a pilot again, but in 2014 it was time to think about getting back to work.

“I was looking for something where I could stay in aviation but not actually still be working as a pilot,” he said. “The job that was most interesting to me is what I’m doing now. I compile aeronautical data from different countries and put that together. I don’t make flight plans, but I actually make the charts and the navigational tools and the data sets that pilots reference when they’re in the cockpit.”

That new job was based in Denver, so the Carrs headed west again. His schedule at Boeing was three days a week in the office and two days at home. When the pandemic hit in 2020, it changed to permanent remote work status.

“Part of the good side of COVID was we showed we were an organization that could telecommute effectively,” Tony said.

Tony Carr works as a geospatial technician for Boeing, creating charts that pilots use on commercial flights.

“That opened up doors to a whole new thought process,” he added. “We had thought as long as I’m in this job, which I enjoy, we need to be where my job is. During the summer of 2020, we came to Bemidji for a kind of test run. I plugged in and did my work, and we were saying this is something that could work for us.”

They enjoyed Colorado’s natural beauty and outdoor activities but found that Bemidji had some of the same qualities. And a colder climate location makes things easier for Tony, whose numerous skin grafts make him susceptible to both hot and cold temperatures. He explained he can always put more clothing on in the cold, but there’s not much defense against the heat.

"The truth is it was getting a little bit expensive as far as the cost of living out there, and in addition to that just overall population growth, congestion, traffic and things that come from living in a big city,” Tony said. “It was starting to wear on Sharon and me.”

He put in a formal request with Boeing to move to Minnesota, and when it was approved, he and Sharon, along with their daughters Loralee, 7, and Madalyn, 4, headed back to Bemidji in June of this year.

Tony found out about 218 Relocate and reached out to Greater Bemidji Assistant Director Erin Echternach, who coordinates the program. The Carrs were reimbursed for their moving expenses, their oldest daughter was enrolled in Northern Elementary, the same school her mother attended, and Tony went about his business of ensuring safe Boeing flights.

“It’s turned out to be great,” Tony said. “I think Bemidji is in a really exciting place. It’s growing and it’s attracting a lot of good people and a lot of exciting things are probably in store for the community as it grows. As telecommuting becomes more common I think the 218 Relocate program is going to be pretty important.

"If people are trying to choose between a couple of towns but this one is going to give them several thousand dollars to help with the move, that’s certainly going to be a positive that could potentially sway them in that direction. It’s paying off for both the city and the individuals who are beneficiaries of that.”

More on 218 Relocate

The 218 Relocate program was created by Greater Bemidji Economic Development to attract professionals to the community. The program has brought more than 20 new individuals and families to the Bemidji area.

With support from the George W. Neilson Foundation and Paul Bunyan Communications, 218 Relocate offers the following benefits to those who perform the majority of their employment duties remotely from a home office or co-working space:

Up to $2,500 in reimbursed moving expenses and/or qualifying telecommuter expenses not already covered by employer/company, including Gigabit internet service.

One-year membership to the LaunchPad co-working space in the historic Mayflower Building ($1,500 value).

Free access to the Community Concierge program, connecting individuals and their families to the community.

Teleworking support and tools through Effective Remote Work (provided by Justin DiRose).

One-year Associate Level membership to the Bemidji Area Chamber of Commerce ($335 value).

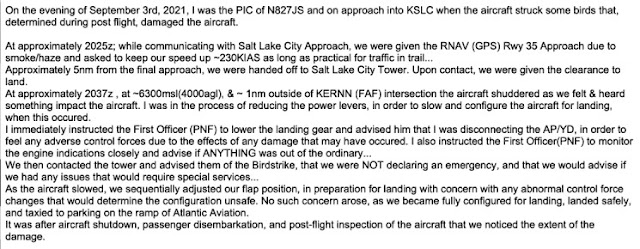

Wreckage from Front Right

Taxiway After Wreckage Recovery

Abrasions and Slash Marks on Taxiway

Slash Marks Oriented Perpendicular to Taxiway, 1 of 2

Slash Marks Oriented Perpendicular to Taxiway, 2 of 2

Right Propeller

The National Transportation Safety Board traveled to the scene of this accident.

Additional Participating Entities:

Federal Aviation Administration / Flight Standards District Office; Richmond, Virginia

Piper; Vero Beach, Florida

Lycoming Engines; Williamsport, Pennsylvania

Airnet Systems Inc; Columbus, Ohio

Investigation Docket - National Transportation Safety Board:

Location: Richmond, Virginia

Accident Number: ERA11LA240

Date and Time: April 11, 2011, 21:27 Local

Registration: N3547C

Aircraft: Piper PA-31-350

Aircraft Damage: Substantial

Defining Event: Aerodynamic stall/spin

Injuries: 1 Serious

Flight Conducted Under: Part 135: Air taxi and commuter - Non-scheduled

Analysis

The twin-engine airplane was scheduled for a routine night cargo flight. Witnesses and radar data described the airplane accelerating down the runway to a maximum ground speed of 97 knots, then entering an aggressive climb before leveling and pitching down. The airplane subsequently impacted a parallel taxiway with its landing gear retracted. Slash marks observed on the taxiway pavement, as well as rotation signatures observed on the remaining propeller blades, indicated that both engines were operating at impact. Additionally, post-accident examination of the wreckage revealed no evidence of any preimpact mechanical failures or malfunctions of the airframe or either engine. The as-found position of the cargo placed the airplane within the normal weight and balance envelope, with no evidence of a cargo-shift having occurred, and the as-found position of the elevator trim jackscrew was consistent with a neutral pitch trim setting. According to the airframe manufacturer's prescribed takeoff procedure, the pilot was to accelerate the airplane to an airspeed of 85 knots, increase the pitch to a climb angle that would allow the airplane to accelerate past 96 knots, and retract the landing gear before accelerating past 128 knots. Given the loading and environmental conditions that existed on the night of the accident, the airplane's calculated climb performance should have been 1,800 feet per minute. Applying the prevailing wind conditions about time of the accident to the airplane's radar-observed ground speed during the takeoff revealed a maximum estimated airspeed of 111 knots, and the airplane's maximum calculated climb rate briefly exceeded 3,000 feet per minute. The airplane then leveled for a brief time, decelerated, and began descending, a profile that suggested that the airplane likely entered an aerodynamic stall during the initial climb.

Probable Cause and Findings

The National Transportation Safety Board determines the probable cause(s) of this accident to be:

The pilot’s failure to maintain adequate airspeed during the initial climb, which resulted in an aerodynamic stall and subsequent impact with the ground.

Findings

Personnel issues Aircraft control - Pilot

Aircraft Airspeed - Not attained/maintained

Factual Information

HISTORY OF FLIGHT

On April 11, 2011, at 2127 eastern daylight time, a Piper PA-31-350, N3547C, operated by Airnet Systems, Inc. as U.S. Check flight 901, was substantially damaged when it impacted a taxiway after takeoff from Richmond International Airport (RIC), Richmond, Virginia. The certificated commercial pilot was seriously injured. Night visual meteorological conditions prevailed, and an instrument flight rules (IFR) flight plan was filed for the flight, which was destined for Charlotte/Douglas International Airport (CLT), Charlotte, North Carolina. The non-scheduled cargo flight was conducted under the provisions of 14 Code of Federal Regulations Part 135.

Two airport firefighters observed the airplane during its attempted departure from runway 20, and during separate interviews, recounted a similar series of events. Both of the firefighters were standing on the airport fire station ramp, located about 1,000 feet east of the intersection between runway 20 and taxiway C. The firefighters reported that the airplane began the takeoff roll normally, but became alarmed as the airplane became airborne before reaching taxiway C, and its pitch increased to an extreme angle. At its maximum pitch angle, the airplane was climbing near vertically, and one of the firefighters remarked that the airplane appeared similar in attitude to an airplane at an air show. He found the airplane's pitch attitude so unusual, he began running toward the airport fire truck with the intent of responding to a crash. The other firefighter continued to watch as the airplane climbed to an estimated altitude about 300 feet above the ground, before it pitched down and briefly leveled. The airplane then pitched down further, and briefly leveled again. The second firefighter then also realized that the airplane would crash, and began preparing to respond.

One of the firefighters remarked that during the initial portion of the takeoff, the airplane's engines sounded normal, smooth, and continuous. The sound then changed as the airplane pitched vertically, giving him the impressions that the engines had "throttled up." He also remarked that the airplane's pitch upward began just about the time the airplane crossed taxiway C, which was located about 2,300 feet from the runway 20 threshold.

According to radar and voice communication data provided by the Federal Aviation Administration (FAA), a radar target correlated to the accident airplane's assigned transponder code began moving from the northern ramp area at RIC toward runway 20 at 2127. About that time the pilot contacted the air traffic control tower and was cleared for takeoff. About 2128:10, the airplane began its takeoff roll from runway 20. Measurement and calculation of the airplane's radar-derived position showed that about 9 seconds later, the airplane had traveled about 950 feet down the runway and reached a maximum groundspeed of about 97 knots. The airplane's reported altitude did not change for another 9 seconds, at which time the altitude increased by 200 feet, about the time the airplane crossed the point where runway 20 intersected taxiway C, and about 1,900 feet from the point where the airplane began the takeoff roll. About 4 seconds later, at 0128:32, the airplane's altitude had increased by another 300 feet, and the calculated groundspeed had decreased to 44 knots. The airplane's calculated climb rate during this timeframe was 3,920 feet per minute. During the next 4 seconds the airplane only traveled 103 feet, and its reported altitude remained constant. The airplane then descended 200 feet during the following 4 seconds, and traveled 270 feet across the ground. No further transponder-correlated radar targets were recorded; however an uncorrelated radar target recorded 5 seconds later placed the airplane 325 feet from the previous correlated radar target and about 200 feet from the initial impact point.

The pilot was seriously injured during the accident sequence and did not regain consciousness until about 1 month after the accident. During a telephone interview conducted about 4 months after the accident, the pilot recalled the sequence of events that transpired immediately prior to and during the accident flight. After performing a preflight inspection of the airplane, the pilot confirmed the airplane's weight and balance as well as the fuel load. The inboard fuel tanks were full and the outboard fuel tanks were about 1/4 full. The pilot then started the engines and performed a run-up check, noting no anomalies. He then taxied the airplane to the fixed base operator where he loaded the cargo. Once the airplane was loaded, he again started the engines, obtained an IFR clearance, and taxied for departure.

After taxiing onto runway 20, the pilot held the brakes and increased engine power to 2,000 rpm, after which he released the brakes and continued increasing the engine power to full. During the takeoff run he rotated the nose upward within the first 1,500 feet of runway, and around 65 knots indicated airspeed. He then pitched the airplane for the climb out airspeed, the blue line on the airspeed indicator. He then tapped the brakes and retracted the landing gear. He also stated that customarily he would retract the landing gear about 3 to 5 seconds after rotation, at an altitude about 200 feet above the ground, and that the landing gear retraction cycle took about 5 seconds.

Once the landing gear had retracted, the pilot stated that he perceived a yawing sensation, with the nose of the airplane gradually pulling to the left, and noted a change in engine sound. He did not note any loud sounds or banging, but did notice a definite difference. He then looked at the manifold pressure gauge and noted that the left engine indicated 0 inches of manifold pressure and the needle was "fluttering." He responded by reducing the throttles of both engines to idle as he wanted to avoid a roll induced when the airplane's airspeed was degraded below the minimum single engine controllable airspeed. The pilot reported that he did not have time to extend the landing gear before the conclusion of the event, and could not recall any of the events that transpired after he closed the engines' throttles.

PERSONNEL INFORMATION

The pilot held a commercial pilot certificate with ratings for airplane singe and multiengine land, and instrument airplane. He also held a flight instructor certificate with ratings for airplane single and multiengine, and instrument airplane. His most recent FAA first-class medical certificate was issued on January 1, 2011 with the limitation, "must wear corrective lenses."

According to the operator, the pilot had accumulated 1,946 total hours of flight experience, 88 of which had been accrued in the 90 days preceding the accident. The pilot had accumulated 31 total hours of flight experience in the accident airplane make and model, all of which were accrued in the 90 days preceding the accident. The pilot began training with the operator on January 27, 2011, and was hired on February 11, 2011. Between February 8 and 10, the pilot completed 4.9 hours of initial flight training in the Beech BE-58, and completed transition training in the accident airplane make and model on February 17, 2011 after 2.1 hours of training.

AIRCRAFT INFORMATION

The accident airplane was manufactured in 1979, and was powered by two Lycoming (L)TIO-540-J2BD engines driving counter-rotating propellers. The airplane's originally certificated maximum takeoff weight was 7,000 pounds; however the airplane had been modified by a supplemental type certificate that increased the maximum takeoff weight to 7,368 pounds. According to the operator, at the time of the accident the airplane was loaded to a gross weight of 6,700 pounds.

The airplane's most recent annual inspection was completed on October 13, 2010, and on that date the airplane had accumulated 17,265 total flight hours. The airplane had accumulated 47 additional flight hours since that time.

METEOROLOGICAL INFORMATION

The 2154 weather observation at RIC included winds from 200 degrees magnetic at 14 knots, 10 statute miles visibility, scattered clouds at 25,000 feet, temperature 24 degrees C, dew point 17 degrees C, and an altimeter setting of 29.70 inches of mercury.

AIRPORT INFORMATION

Richmond International Airport included three runways arranged in a semi-triangular form. Runway 02/20, which was 6,607 feet long by 150 feet wide, was the western most runway on the airport and was paralleled by two taxiways, U and A, staggered to the west. Taxiway C intersected runway 20, taxiway U, and taxiway A, about 2,500 feet from the runway threshold. The airport elevation was 167 feet.

WRECKAGE AND IMPACT INFORMATION

Abrasions and observed on taxiway U were identified as the airplane's initial impact point, and began about 3,500 feet from the approach end of runway 20, and extended about 260 feet south along the taxiway, to where the main wreckage came to rest, oriented roughly 160 degrees magnetic. There were three distinct areas of abrasions, with one area oriented parallel to the taxiway and exhibiting paint transfer of similar color to the airplane's fuselage and wings, while two other areas of abrasions were oriented roughly perpendicular to the taxiway. The perpendicular abrasions consisted of four slash marks in the concrete roughly 2 to 6 inches in length spaced about 4 inches apart.

The majority of the airframe exhibited extensive impact and post-impact fire-related damage, and the empennage was almost completely consumed by fire. The pilot and co-pilot seats remained attached to their respective floor tracks, but their pre-accident positions could not be determined. Most of the cargo netting was fire-damaged, though the remaining portions of net and attaching hardware appeared secured. About 720 pounds of cargo was recovered from the aft portion of the fuselage following the accident, and the distribution of the recovered cargo placed the airplane within the normal weight and balance envelope. Flight control cable continuity was traced from the elevator, rudder, and ailerons to the forward portion of the cabin, and all breakages of the cables exhibited features consistent with tensile overload. Measurement of the elevator trim jack screw correlated to a roughly neutral elevator trim setting.

The right engine exhibited fire and impact damage. The propeller remained attached to the propeller flange with portions of all three blades attached to the propeller hub. The propeller blades were arbitrarily labeled A, B, and C. The blade marked A was bent 90 degrees toward the cambered surface about 1-foot outboard of the hub, and separated about mid span, with the outboard portion not observed. The blade marked B separated 4 inches outboard of the propeller hub with the remaining portion not observed. The blade marked C was twisted toward the cambered side and exhibited S-bending and chordwise scratching. All of the blades were free to rotate within the hub. The propeller governor remained attached and undamaged, oil screen was absent of debris.

The engine was partially disassembled for examination. The crankshaft was rotated using a tool at the vacuum drive pad, and compression and valvetrain continuity was confirmed to all cylinders. The number 1 cylinder exhibited relatively less compression than the other cylinders and was impact damaged on its bottom side. The cylinder was removed for further examination with no damage to the piston or rings and a small rust spot noted near the top of the ring sweep area. No anomalies were noted when examining the interiors of the remaining cylinders with a lighted bore scope.

The engine driven fuel pump was free to rotate and displayed no binding. The fuel injector servo was impact damaged and partially separated from the engine. The mixture control arm was damaged, and none of the control positions were considered reliable due to impact-related damage. The fuel servo regulator section fasteners and safety wires were intact, and the brass plug was snug. The regulator section was disassembled for examination, with no damage to the rubber diaphragms noted. The stem that passed through the fuel diaphragm was broken in the threaded portion. The stem was examined in detail, with a small portion of the fracture smeared, and the remaining displaying dimple-shaped features consistent with ductile overstress. Neither fracture surface displayed any features consistent with a fatigue fracture.

The dual magneto remained attached to the engine, with no damage noted. The magneto was removed, and rotation of the drive shaft produced spark from all 12 ignition leads. All 12 spark plugs were removed and appeared light to dark gray in color, and exhibited normal wear. The ignition harness was fire damaged and not tested.

The oil suction screen and oil filter were removed inspected with no metallic debris noted. The turbocharger remained attached to the engine, light brown combustion products were noted on the turbine wheel, and the turbine was free to rotate.

The left engine exhibited fire and impact damage. The propeller remained attached to the propeller flange with portions of all three blades attached to the propeller hub. The propeller blades were arbitrarily labeled A, B, and C. The blade marked A was bent aft 90 degrees at about mid-span, tip was curled aft, exhibited leading and trailing edge gouges. The blade marked B was separated about 18 inches outboard of the hub and exhibited twisting. The blade marked C was curved forward, separated at about 3/4 span, and exhibited chordwise scoring, with the tip curled forward. All blades were free to rotate within the hub. The propeller governor remained attached and undamaged, oil screen was absent of debris

The engine was partially disassembled for examination. The crankshaft was rotated using a tool at the vacuum drive pad, and compression and valvetrain continuity was confirmed to all cylinders. No anomalies were noted when examining the interiors of the cylinders with a lighted bore scope.

The fuel servo remained attached, with no external damage noted. The servo was disassembled and a small amount of fuel was found in the fuel regulator section. No damage was noted to the fuel or air diaphragms. The engine driven fuel pump rotated freely by hand.

The dual magneto remained attached to the engine, with no damage noted. The magneto was removed, and rotation of the drive shaft produced spark from all 12 ignition leads. All 12 spark plugs were removed and appeared light to dark gray in color, and exhibited normal wear. The ignition harness was fire damaged and not tested.

The oil suction screen and oil filter were removed inspected. The oil filter media contained a small amount of carbon and a trace amount of shiny, non-ferrous metallic particles. The turbocharger remained attached to the engine, light brown combustion products were noted on the turbine wheel, and the turbine was free to rotate.

ADDITONAL INFORMATION

Pilot's Operating Handbook and Performance Calculations

The accident airplane's Pilot's Operating Handbook procedure for a normal takeoff dictated that while holding the brakes, the throttles should smoothly be advanced forward to takeoff power. The procedure further stated, " At 85 KIAS [knots indicated airspeed], rotate to a 10° pitch attitude and allow the aircraft to fly off. Maintain a pitch attitude which will result in acceleration of the aircraft to 95 KIAS at 50 feet. Before airspeed reaches 128 KIAS, retract the landing gear. Continue acceleration to the desired climb airspeed." The procedure for departing from a short field varied slightly and advised that after verifying that the engines were set to maximum continuous power and releasing the brakes, "At 76 KIAS, rotate the aircraft to achieve an attitude that will result in an initial climb airspeed of 92 KIAS. Maintain 92 KIAS until the barrier has been cleared. After the barrier has been cleared, retract the landing gear, the flaps and accelerate to 104 KIAS (best single engine angle of climb)."

The performance charts contained within the Pilot's Operating Handbook detailed the airplane's expected performance dependent on a variety of environmental, aircraft loading, and aircraft configuration parameters. According to the "Normal Takeoff Distance Over 50 Feet" performance chart, 1,950 feet of runway distance were required for the airplane to initiate a takeoff and climb to an altitude greater than 50 feet above ground level. The airplane's calculated "Normal Accelerate-Stop Distance" for aborting a takeoff at an airspeed of 85 knots was 3,100 feet. According to the "Multi-Engine Climb" performance chart, the airplane's expected climb performance with the landing gear and flaps retracted, and a best rate of climb airspeed of 106 knots, was 1,800 feet per minute. The airplane's calculated single engine climb rate with the inoperative engine's propeller feathered, the landing gear and flaps retracted, and a climb airspeed of 106 knots, was 225 feet per minute. The airplane's published minimum controllable airspeed with one engine operating was 76 knots, and the airplane's calculated stall speed given its configuration at the time of the accident was 74 knots.

Pilot Tony Carr